Submersible Mixer

LK-QJB Submersible mixer is used for municipal sewage treatment plant and industrial wastewater treatment plant to produce low tangential flow with force, also can be used for create a flow for circulation, nitrification, denitrification and phosphorus removing.

Description

LK-QJB Submersible Mixer Sewage Treatment Plant

Overview

|

LK-QJB Submersible mixer is used for municipal sewage treatment plant and industrial wastewater treatment plant to produce low tangential flow with force, also can be used for create a flow for circulation, nitrification, denitrification and phosphorus removing.

Submersible mixer operation video

|

|

Features

|

●Compact structure, light weight, easy to operate and maintenance, simple installation; |

|

●Self-cleaning blade, preventing debris from twining or blocking; |

|

●Lowers energy consumption,high aeration rate preventing sedimentation; |

|

●Two rows of independent mechanical seal, longer service life; |

|

●Class F insulation of motor winding, motor protection grade IP68, imported permanent -lubricated maintenance-free bearings, chamber leakage detection, motor winding overheating protection; |

|

|

Working Conditions

●Liquid temperature: ≤ 40℃

●PH:5~9

●Liquid density:≤1150kg/m3

●Max working depth: 20m

●Motor : IP 68 , 7/24 Continuous working

●Motor MUST diving in water while operating

Parameters

|

LK-QJB Submersible Mixer |

||||||

|

Model |

Power(KW) |

Current(A) |

Impeller(mm) |

Speed(r/min) |

Weight(KG) |

Thrust(N) |

|

QJB0.37/6-220/3-960/S |

0.37 |

1.3 |

220 |

960 |

45 |

138 |

|

QJB0.55/4-220/3-1480/S |

0.55 |

1.6 |

220 |

1480 |

45 |

145 |

|

QJB0.85/8-260/3-740/S |

0.85 |

4 |

260 |

740 |

55 |

180 |

|

QJB1.5/6 260/3-960/S |

1.5 |

4 |

260 |

960 |

55 |

260 |

|

QJB2.2/8-320/3-740/S |

2.2 |

8 |

320 |

740 |

110 |

580 |

|

QJB4/6-320/3-960/S |

4 |

12 |

320 |

960 |

115 |

690 |

|

QJB1.5/8-400/3-740/S |

1.2 |

5.8 |

400 |

740 |

100 |

600 |

|

QJB2.5/8- 400/3-740/S |

2.5 |

9 |

400 |

740 |

100 |

800 |

|

QJB3/8-400/3-740/S |

3 |

11 |

400 |

740 |

100 |

920 |

|

QJB4/6-400/3-960/S |

4 |

12 |

400 |

960 |

100 |

1200 |

|

QJB4/12-620/3-480/S |

4 |

14.2 |

620 |

480 |

184 |

1400 |

|

QJB5/12-620/3-480/S |

5 |

18.2 |

620 |

480 |

184 |

1800 |

|

QJB7.5/12-620/3-480/S |

7.5 |

28 |

620 |

480 |

229 |

2600 |

|

QJB10/12-620/3 480/S |

10 |

32 |

620 |

480 |

229 |

3300 |

|

QJB15/12-620/3-480/S |

15 |

43 |

620 |

480 |

260 |

4000 |

|

QJB18.5/12-620/3-480/S |

18.5 |

51 |

620 |

480 |

276 |

4400 |

|

QJB22/12-620/3-480/S |

22 |

60 |

620 |

480 |

290 |

5300 |

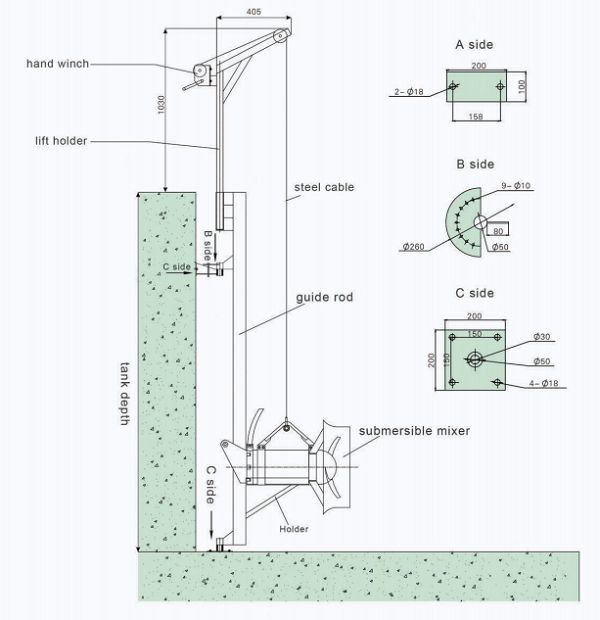

Installation

Installation Ⅰ

1. Tank depth H <3m

2. Direction can be adjusted in horizontal and vertical

3. Depth of guide rod is 3 meters

Installation Ⅱ

1. When depth> 4m, need add another side spport on guide rod.

2. The connection shall be expansion bolt between side support & tank wall, holder & tank bottom.

3. Please inform tank depth when you put order to us.

Installation Ⅲ

1. When depth> 4m, need add another side spport on guide rod.

2. The connection shall be expansion bolt between side support & tank wall, holder & tank bottom.

3. Please inform tank depth when you put order to us.

Blender operating

The installation and positioning of the submersible mixers will have great impact on the mixingeffectiveness.

ln order to achieve the desired operation effect, we suggest that users refer to the followingoperation mode diagram and reasonably choose the installationform of the blender.

On-site Application

Send Inquiry

You Might Also Like